Descriptions:

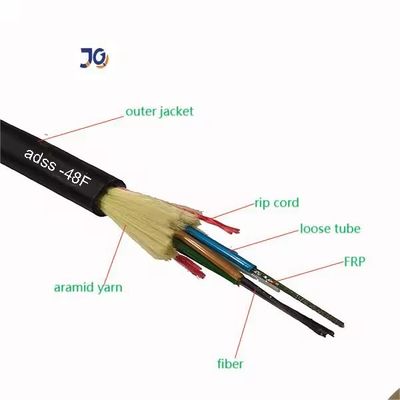

The SM fibers are placed in a loose tube made of a high modulus plastic, the tubes are filled with a water-resistant filling compound, A piece of FIBER REINFORCED PLATIC(FRP) locates in the centre of core as a non-metallic strength member. The tubes ( and fillers ) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminate (APL) is applied around the cable core, which is filled with the filling compound to protect it from water ingress. Then the cable core is covered with a thin PE inner sheath. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

![]()

Application

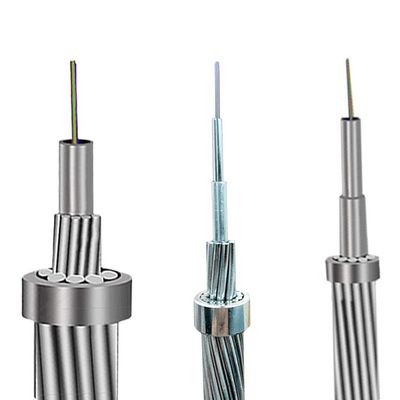

1. Laying method: Direct buried

2. Suitable for long-distance trunk and LAN communication.

3. Fiber type: SM

![]()

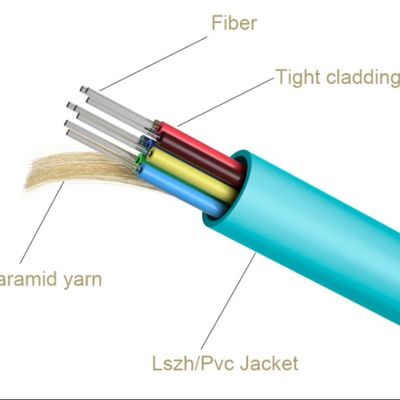

Characteristics:

Double sheaths construction

Accurate fiber excess length ensures good mechanical and temperature performance.

Specially designed compact structure is good at preventing loose tubes from shrinking.

High strength loose tube that is hydrolysis resistant and special tube filling compound ensure a citical protection of fiber.

Moistureproof and ratproof, crush resistance and flexibility.

![]()

The following measures are taken to ensure the cable watertight:

1) Single fiber reinforced plastic as the central strength member

2) Loose tube filling compound

3) 100% cable core filling

4) APL moisture barrier

5) PSP enhancing moisture-proof

6) Water-blocking material

Packaging Details

1.Wooden reel, 1000m/reel, 2000m/reel, 3000m/reel, customer's requirements are also welcomed;

2.Inner packed in fumigated wooden drum, and outer covered by polyethelene sheet, then sealed by strong wooden battens.

![]()

Delivery

For large orders: by sea (LCL or FCL)